Grate Firing Systems

We set new standards with our proprietary grate technology. Our high performance combustion systems for waste wood, household waste and refuse-derived fuels (RDF) enable efficient thermal utilization and sustainable energy generation, from the tried and tested fuel feed to the grate system adapted to the fuel through to the robust slag removal system.

We supply the complete solution as well as individual components such as feed hopper, chute and pusher, ignition and support burner, SNCR, air preheater cleaning device, etc. – innovative, robust and from a single source.

Grate Systems

Our grate systems of various designs are built for steam generator capacities of up to 150 t/h of steam. Thanks to continuous further development based on operational experience, the use of modern design elements and the use of tried and tested materials, our mechanical grate firing systems are at the forefront of today’s technology. Whether in industrial power plants for pure steam and electricity generation or in waste-to-energy plants, the grate firing systems from Power Service Solutions are used in almost all areas of energy conversion and are always optimally adapted to the specified requirements.

Environmentally friendly incineration requires special concepts and measures for domestic and municipal waste, commercial waste, refuse-derived fuel (RDF), residual waste disposal and biomass of all kinds. Depending on the waste calorific values, different grate systems are used. Medium and high calorific value waste fuels require grate bar cooling systems, such as our own water-cooled moving grate system. Low or medium calorific value waste fuels, use patented air-cooled grate bars.

Waste-to-energy plants that have been in operation for many years can be upgraded with new technical designs as part of conversion and modernization measures. The protection systems have been redesigned over recent years, particularly in the area of fuel feeding. The weak-point analyses are carried out allow a plant to be operated much more economically once the appropriate upgrading measures have been implemented.

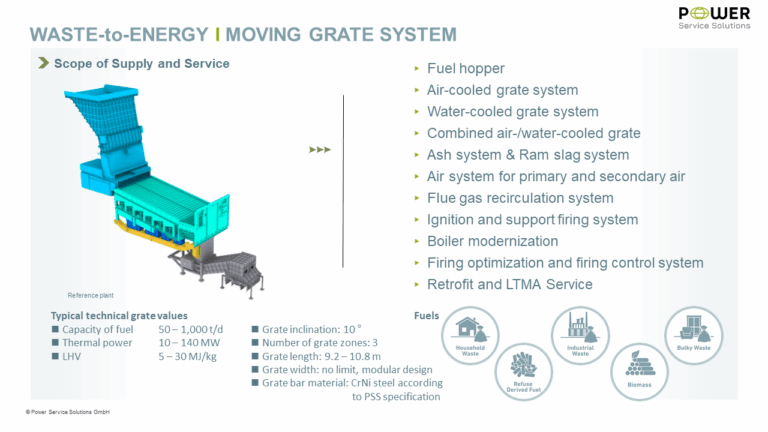

Moving Grate System

The Power Service Solutions moving grate is characterized by its robust design and high throughput capacity. External hydraulic drives control the feed and return strokes of the movable rows of grate bars in each grate zone in accordance with the control requirements. The fixed and moving rows of grate bars are arranged alternately one behind the other in a grate track. Enabled by the PSS grate bar design, the uniform motion sequence and the long stroke movement in the feed result in a smooth furnace operation. In contrast to a short stroke process, this motion sequence is characterized by less wear. Another advantage of the long stroke is the additional cooling effect due to the overlapping of the grate bars and longer life.

In addition to the low exchange rates of the grate bars, the geometry of the grate bars, the air flow and the combustion chamber geometry guarantee the lowest combustion related emissions. The downstream steam generator also benefits from this, as the availability of these systems shows.

The specifications for the operation and maintenance of the grate firing system are provided by Power Service Solutions in a comprehensible manner with implementation of control logic in the main control system.

Grate Bars for Moving Grates

The selection of the grate bar colling medium depends on the specific energy potential of the fuel: air-cooled grate bars are used for low calorific value waste fuels and water-cooled grate bars are used for higher calorific fuels, permitting higher thermal loads.

The design of the grate system is constructed in a way that a change between water-cooled and air-cooled grate bars can be made at any time without any design change. In the transition area from low to higher calorific value wastes, it is possible to combine both types of cooling. The grate bars of the high thermal load grate zones are cooled by water, while the grate bars of the burnout zone are cooled by air.

The grate surface, developed by Power Service Solutions, enables a process optimized reduction in the primary air ratio, together with a reduction in excess air, controlling primary NOx emissions, without impacting grate bar life.

Characteristics and advantages of the PSS moving grate

- Design and construction

- Availability > 8,000 operating hours per year

- Increased operational reliability

- Extended maintenance intervals

- Reduced ongoing maintenance costs

- Longer service life due to reversible and wear-resistant end-face grate bar technology

- Reduced spare parts inventory

Air-Cooled Grate Bars

Our patented air-cooled grate bars are designed for longer service life. This is achieved by a second wear face concealed behind the head face and thus protected from temperature induced corrosion. In the event of thermal wear of the outer head surface, the second wear face ensures the continued function of the grate bar and thus an extension of the overall service life. The grate bar can also be supplied as a reversible grate bar for two-ended use and a further extension of the service life observed.

Application range: Unrestricted usability for low up to medium calorific values.

Water-Cooled Grate Bars

The cooling water ducts are cast into the iron grate bars, which ensures water-tightness even at higher temperatures. Furthermore, the cast-in iron ducts guarantee a defined flow. This avoids vortex-induced dead spaces of angular ducts, which entail a risk of overheating. At the same time, an optimum cooling effect of the entire grate bar surface is achieved.

Application range: Unrestricted usability for medium up to high calorific values.

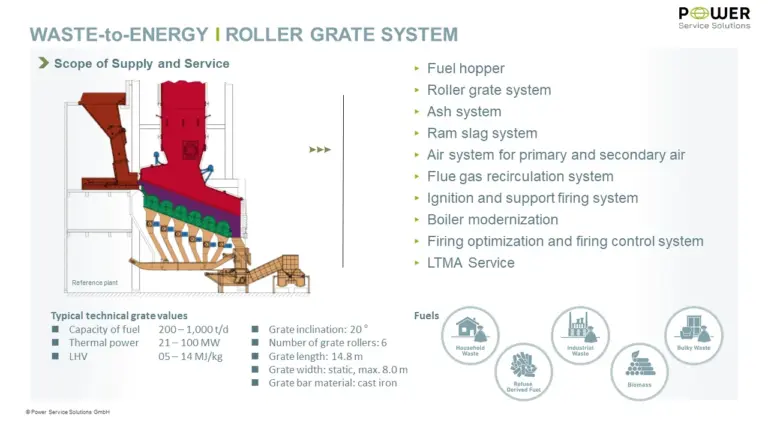

Roller Grate System

In the past, roller grates were often built in designs with direct current firing. Due to their limited throughput capacity, there is rarely a need for new constructions today. Due to their long service life, the focus is on providing spare parts for existing operators. The robust roller grate system from Power Service Solutions has a modular design due to its six grate rollers and is used for low or medium calorific residues. Part of the circumferential roller surface passes through the combustion chamber in a continuous alternation, while the side facing away from the combustion chamber is air-cooled. This interaction reduces the thermal load on the grate lining and enables the very long service life of this grate system.

Ash Handling and Slag Removal System

Ash handling and slag removal systems for grate firing systems of various types have been part of Power Service Solutions production and scope of supply for many decades.

Scope of delivery of the Ash Removal System

- Slag chute

- Ram deslagger

- Wet deslagger apron feeder

- Trough chain conveyor (wet)

- Vibrating feeder

- Butterfly damper in the slag chute

- Gate valves

- Spare and wear part delivery

Advantages

- Proven combination of mechanical conveyor systems

- Robust design

- High availability

- Maintenance friendly design

- Low operating and maintenance costs

- Particularly suitable for transporting bulky and large items

Ram Deslagger for Grate Slag

Robust, efficient and low-maintenance.

The slag remover consists of a solid steel sheet housing with an internal drive shaft and a discharge ram. The drive shaft is powered by externally mounted hydraulic cylinders. High force transmission to the ram is achieved through large external and internal lever arms.

Trough Chain Conveyor for Grate Drop Ash

Reliable under extreme conditions.

The trough chain conveyor is designed as a two-strand chain conveyor. The conveyor chain used is a drop-forged forked chain with carriers. The main trough is horizontal, while the drive and deflection segments are arranged at an incline, so that the drive and deflection shafts with their respective bearings are positioned above the water level.