Combustion & Decarbonization

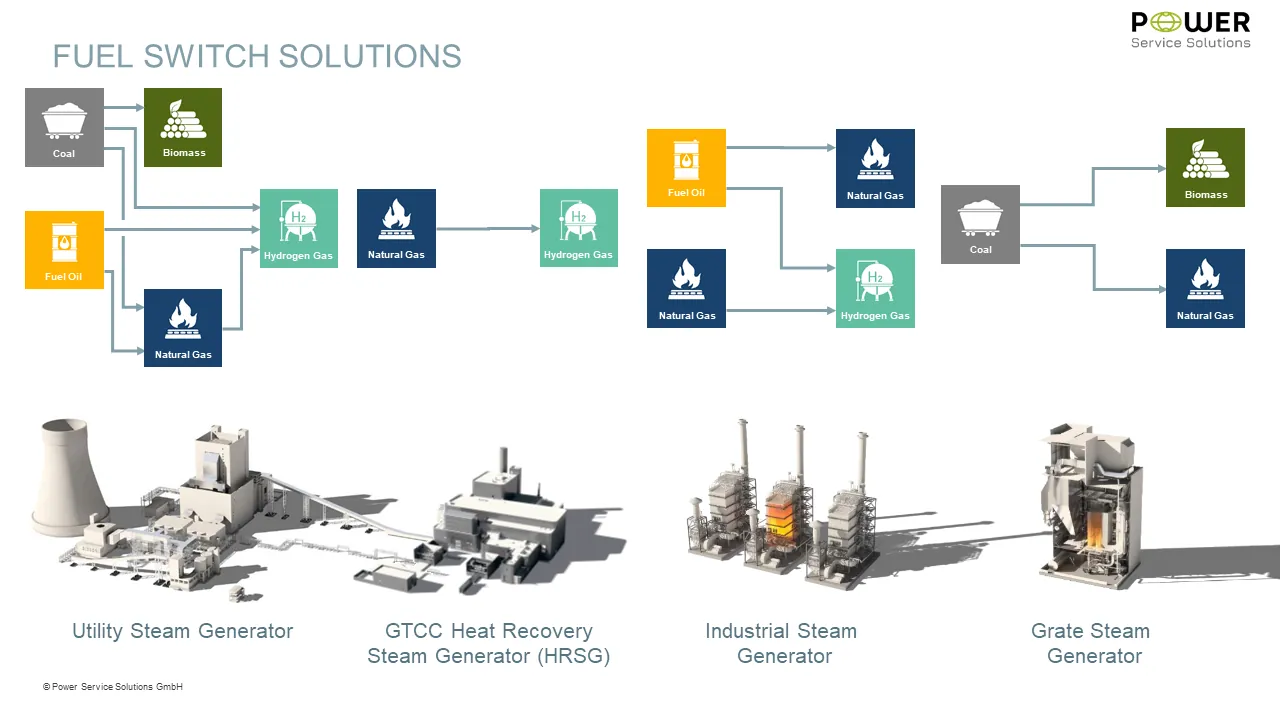

Whether it is a large steam generator, a combined cycle plant, an industrial boiler, or a grate-fired boiler, Power Service Solutions has the necessary experience for fuel switching to fuels such as wood pellets and other biomasses, waste, natural gas, etc. and can demonstrate this with a variety of completed reference projects.

At the outset, we ensure that the boundary conditions are properly coordinated with regard to the fuels to be used, the required system output and the environmental regulations, customer guidelines to be complied with and the operating parameters of the boiler on the current fuel.

In the case of a fuel changeover, it is necessary to integrate the new system components into the existing boiler structure or into the overall process. This is why the description and definition of the interfaces to the existing system is very important for our customers and for us.

Often a fuel change cannot be achieved by simply replacing components. Instead, an innovative and cost effective overall concept must be developed. The more flexible the solution is with regard to the use of new fuels, the greater the value for the plant operator. This always has the objectives of low operating costs, high availability and the lowest possible maintenance costs.

The first step towards a retrofit is often a feasibility study. This study outlines and analyzes the necessary changes. Depending on the available documentation, it is possible to create process simulations, thermal boiler models and, if necessary, computation fluid dynamic simulations. Such models are built from plant drawings and calibrated against the existing performance, giving confidence in the performance predictions and necessary equipment duties using the new fuel.

Based on this study, a proposal for the necessary modifications can then be prepared in the next step. This proposal will list and evaluate all the required measures for the planned fuel switch and predict the plant performance with the new fuel.