Steam Generation

Power Service Solutions provides a complete array of services for the modernization of fired steam generators, of all types of design and size. We deliver customer oriented service and rehabilitation for utility steam generators (boilers) including all components of the water and steam circuit, such as drums, valves, heat transfer surface, piping, etc.

The replacement or new construction of steam generators of all types remains part of our portfolio.

In addition, as an engineer and manufacturer of numerous steam boiler systems in the EMEA region, Power Service Solutions is the ideal partner for modernization and spare parts requirements. Our experience in the construction of power plants extends from Europe to the Middle East and Africa, allowing us to respond quickly and flexibly to customer needs across borders.

Plant optimization

Whether large power plants or industrial steam generators, many power plant operators must modernize or renovate their plants if they want to operate them in an environmentally friendly and profitable manner in the coming years, for example:

- Stricter emissions limits

- Operational flexibility

- Fuel flexibility

- Lifetime extension

- Digitalization

Our engineers at Power Service Solution pursue a holistic approach in the development and evaluation of plant optimizing solutions. Our extensive experience is proven by a large number of references, both in the construction and modernization of energy systems. On this basis, we are able to offer customized and tailor-made solutions for every requirement and application. The measures range from preparatory studies, repairs and the installation of spare parts to the installation of new upgraded components and system parts or complete boiler plants.

Our know-how covers a wide range of fuels for different types of boilers:

- Lignite

- Bituminous coal

- Gas

- Oil

- Biomass

- Waste

- Furnace gas (blast furnace gas)

- Refinery gas

Process engineering inspection of the steam generators

Operational assessment (Plant operation)

Input Values:

- Plant documentation, maintenance records, reports on equipment failure

- Operating data and observations

- Measurements (e.g. fuel, mill, exhaust gas)

- Customer observations

Results:

- Thermal recalculation

- Comparison with the original design

- Compliance with the latest safety standards and emission guidelines

- Proposal for plant optimization (state of the art), price indication

- Support with the plant specific investment assessment

Mechanical engineering inspection of the steam generators

Mechanical assessment (Plant not in operation)

Input Values:

- Plant documentation, maintenance records, reports on damage

- Visual inspection

- Tests and inspections (NDT, pipe samples)

- Customer observations

Results:

- Visualization of problem areas, correlation with operational assessment

- Service life assessment and forecast

- Proposal for system optimization (state of the art), price quotation

- Support with system specific investment assessment

Boiler Types

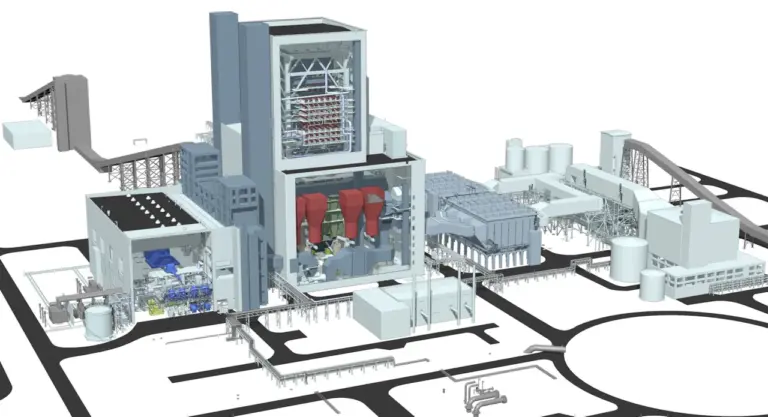

- Benson® once through steam generators as tower boilers or two-pass boilers

- Water tube boilers (natural circulation)

- Industrial boilers / industrial steam generators

- Waste heat boiler (process)

- Waste heat boiler (downstream of gas turbine)

- Waste incineration plants

- Special boilers (chemical industry)

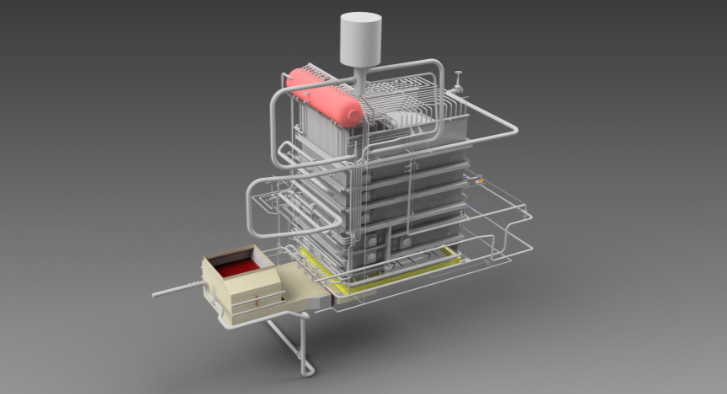

Industrial boiler/Industrial steam generator

Our industrial boilers are used in almost all industries where steam is required. In addition to new construction, we also offer the modernization of existing systems to increase their efficiency. Our boilers and burners can be reliably operated with a variety of fuels, such as oil, gas, coal, biomass, blast furnace and coke oven gas, etc.

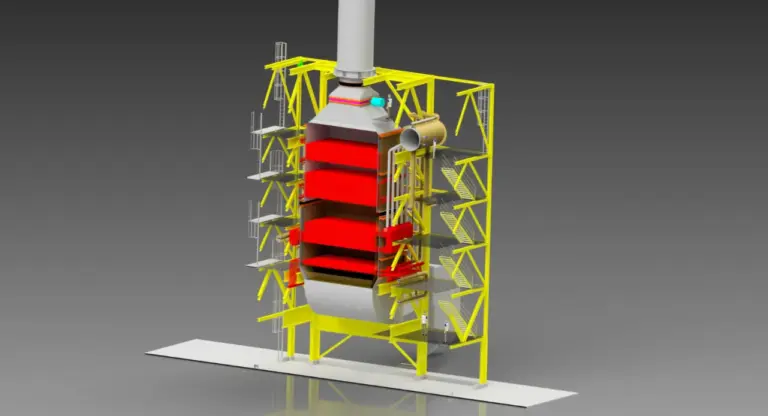

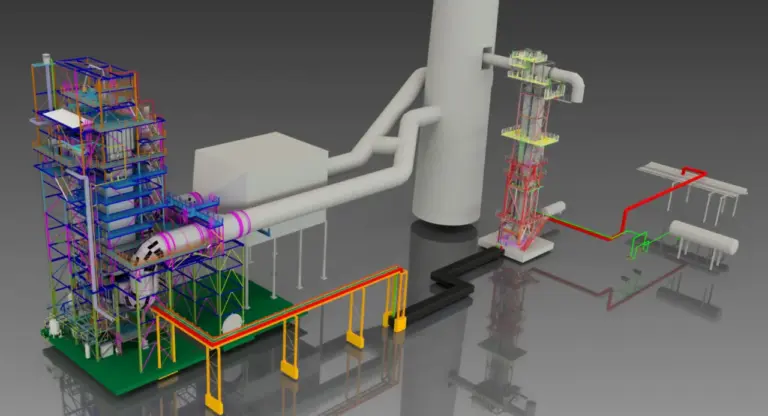

Waste-to-Energy Boiler

For waste incineration plants, Power Service Solutions offers steam generators that are specially designed for the extreme operating requirements in terms of emissions and WID compliance, corrosion, contamination, slagging, material load, partial load behavior and plant dynamics.

Depending on the requirements of the customer and the local situation, either horizontal or vertical design types can be offered.

The steam generators are designed according to the Benson process.

The Benson process is an advanced operating principle in which water is converted directly into steam under high pressure. This process enables higher efficiency through the use of higher steam temperatures and pressures and a more compact boiler design. It is particularly suitable for applications that require high performance.

Although new utility steam generators are no longer being built in Europe due to the coal phase out, through decades of experience in the design and construction of this type of boiler, Power Service Solutions has the know-how to optimize their operation or to convert them to other fuels.